Diaphragm pumps (especially AODD) are positive displacement, great for viscous/abrasive/corrosive fluids, self-priming, and dry-run safe. Submersible pumps are centrifugal, best for clean/deep water but need submersion and priming in some cases.

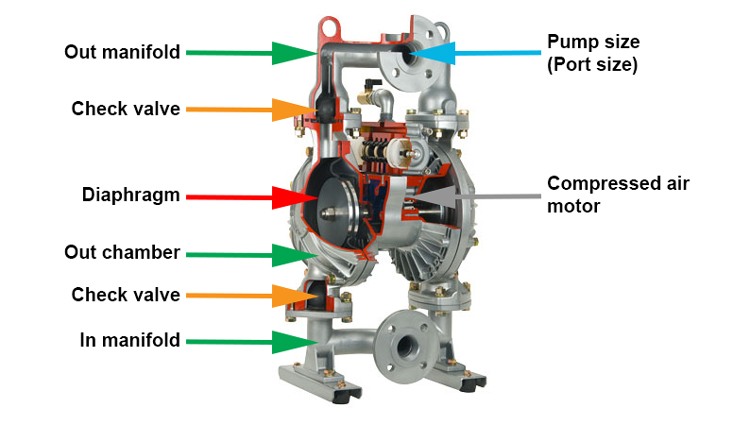

Most common — powered by compressed air, double diaphragms for reliable transfer.

Electrically driven for continuous duty & energy efficiency.

Submerged versions for specific dewatering or sump applications.

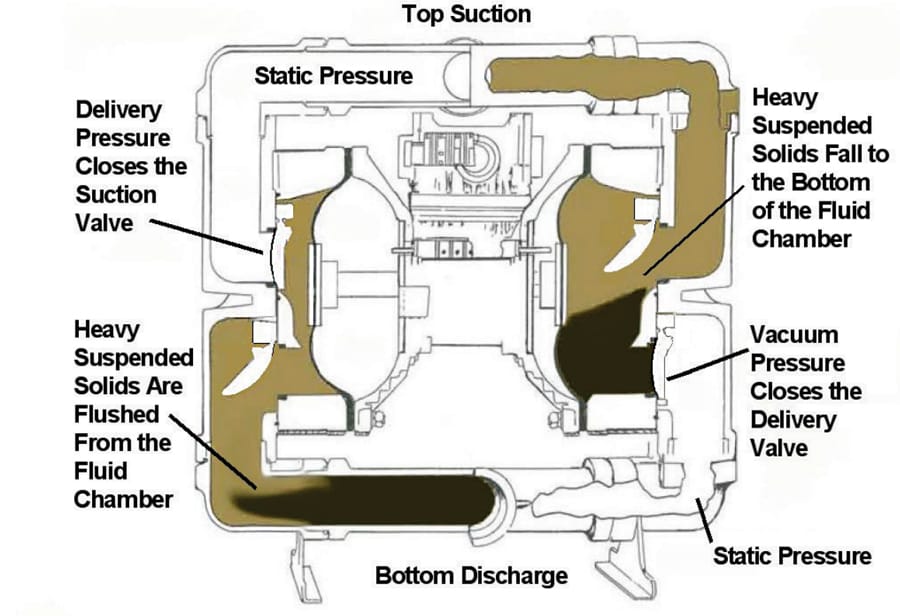

Swipe through to see internal operation →

.png?width=575&name=AODD_Pump_Components_Graphic-2%20(1).png)

Swipe for examples in action →

Swipe to see flow vs pressure examples (air pressure affects output) →

| Parameter | Typical Range |

|---|---|

| Flow Rate | 1 – 285 gpm (4 – 1,079 l/min) |

| Pressure | Up to 100–200 psi (7–14 bar) |

| Suction Lift | Up to 25 ft (7.6 m) |

| Solids Handling | Up to 1/4" – several inches (model dependent) |

| Temperature | -40°F to 350°F (-40°C to 177°C) |

| Materials | Aluminum, SS316, Polypropylene, PVDF |