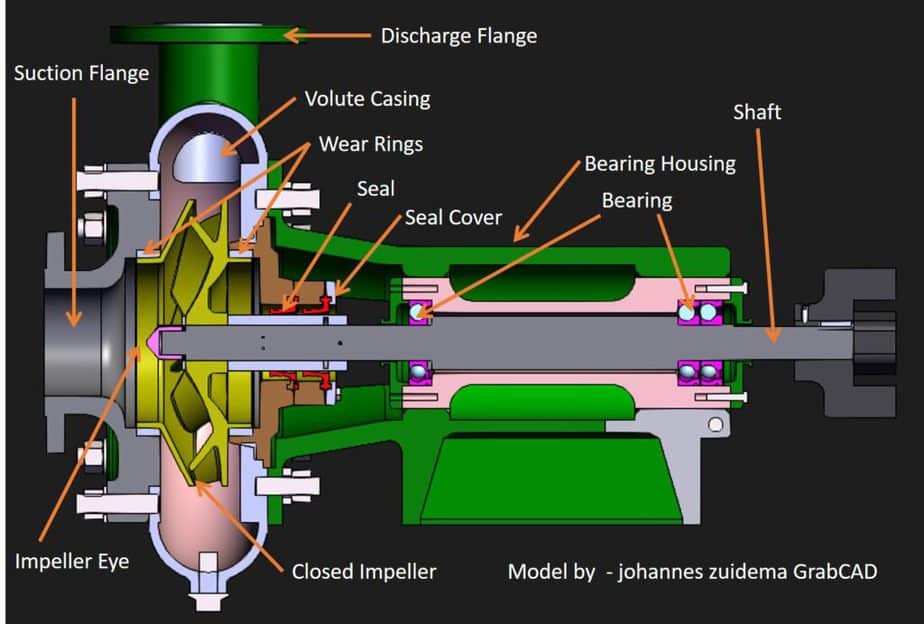

Centrifugal pumps use a rotating impeller to impart velocity to the liquid, converting kinetic energy into pressure as it exits the volute casing. Fluid enters axially at the eye of the impeller and is discharged radially. This design excels in high-flow, moderate-head applications with clean or lightly contaminated liquids.

Explore the main parts of a typical single-stage horizontal end-suction centrifugal pump:

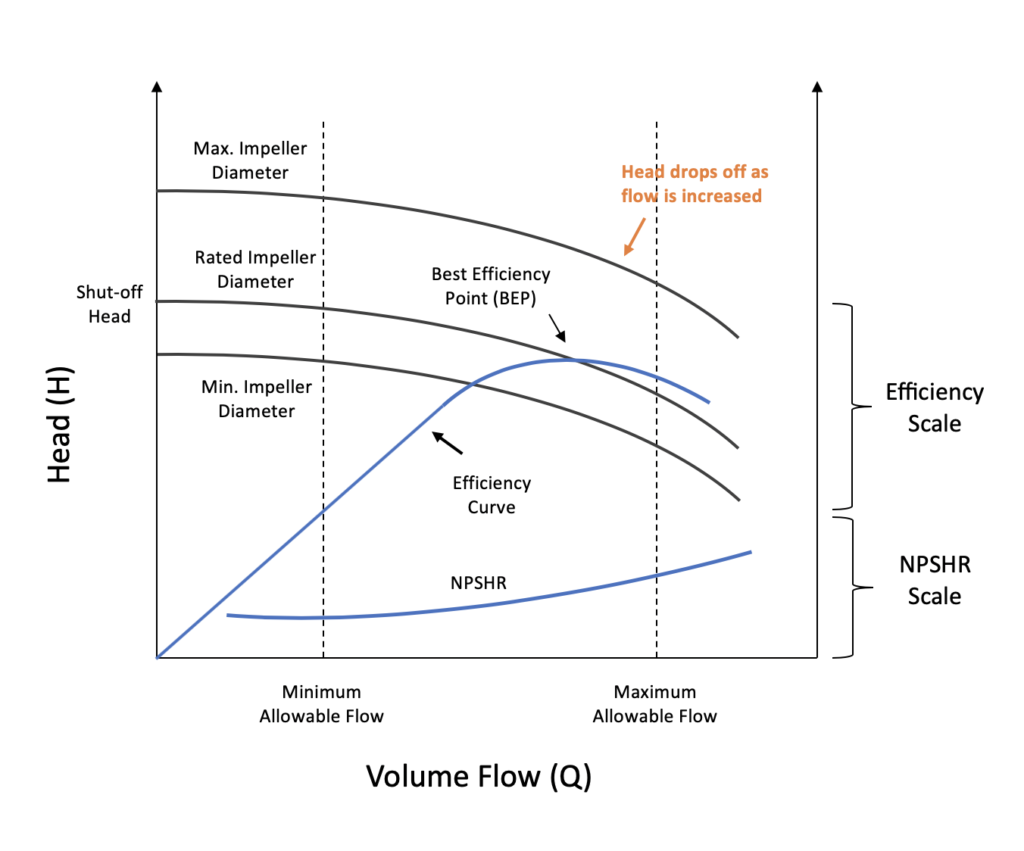

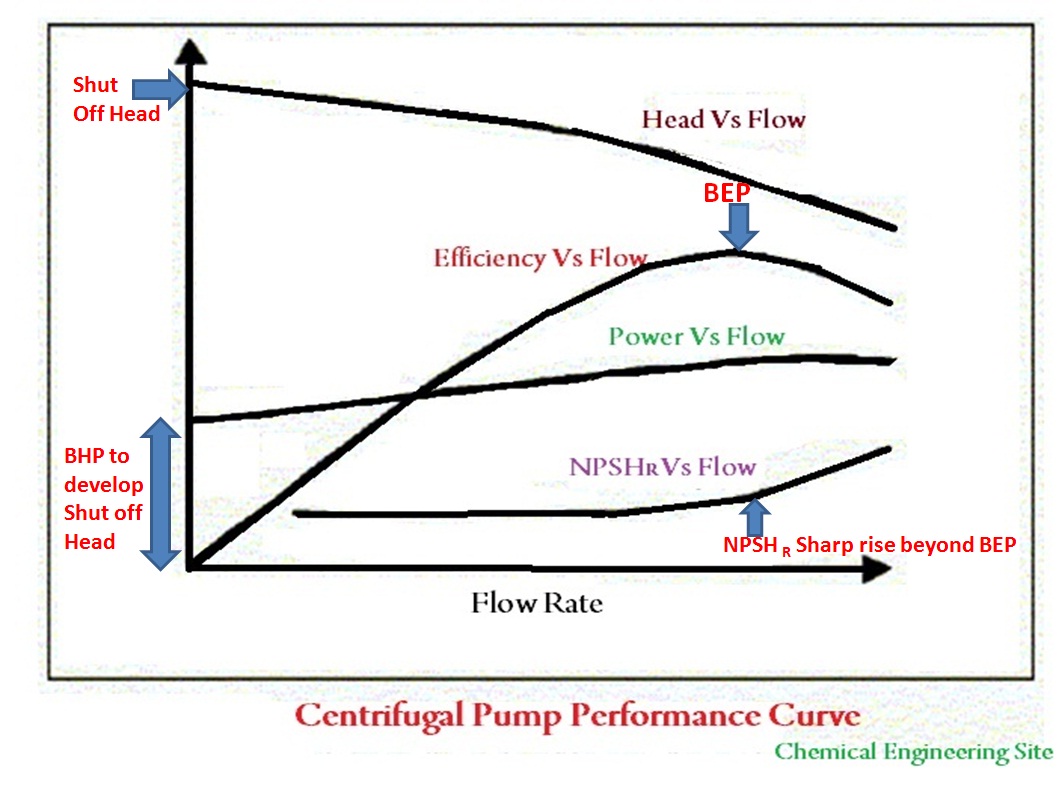

Centrifugal pump performance is shown on curves plotting Head (H) vs Flow (Q), along with efficiency, power, and NPSHr. The curve shows an inverse relationship: higher flow results in lower head. The Best Efficiency Point (BEP) is the optimal operating zone for maximum efficiency and longevity.

Here are examples of typical performance curves (including efficiency and NPSH):

View examples of horizontal end-suction centrifugal pumps in industrial blue finish (common for EN 733-compliant models):

Match your needs to the pump curve: Calculate required flow (Q) and total dynamic head (TDH). Aim to operate near the BEP (within ±10–20%). For EN 733-compliant pumps, typical ranges include:

Consult the spec sheet for exact curves and select based on efficiency, materials, and application.